High-Quality Homogenizer Emulsifier Mixers

# High Quality Homogenizer Emulsifier Mixers for Industrial Efficiency

What Are Homogenizer Emulsifier Mixers?

Homogenizer emulsifier mixers are advanced industrial machines designed to blend, emulsify, and homogenize ingredients into a uniform consistency. These mixers are essential in industries like pharmaceuticals, cosmetics, food processing, and chemicals, ensuring smooth, stable, and high-quality end products. YUANYANG’s mixers combine precision engineering with cutting-edge technology for superior performance.

Key Features of YUANYANG Mixers

High Shear Mixing Technology

Our homogenizer emulsifier mixers utilize high shear forces to break down particles, ensuring ultra-fine dispersion and emulsification. This results in smoother textures and enhanced product stability.

Vacuum-Compatible Design

YUANYANG’s vacuum homogenizers and emulsifiers prevent air entrapment, reducing oxidation and improving product shelf life—ideal for sensitive formulations.

CE-Certified & Reliable

All YUANYANG mixers meet stringent CE safety standards, guaranteeing compliance with EU regulations. Built for durability, they deliver consistent results in demanding environments.

Applications Across Industries

Cosmetics & Personal Care

Achieve flawless creams, lotions, and serums with our homogenizer emulsifier mixers, ensuring even distribution of active ingredients.

Food & Beverage

From sauces to dairy products, our mixers provide uniform blending, enhancing taste and texture while maintaining hygiene standards.

Pharmaceuticals

Precision mixing ensures uniform drug formulations, meeting strict industry regulations for safety and efficacy.

Why Choose YUANYANG?

With over 15 years of expertise, YUANYANG provides turnkey solutions, including installation support and technical training. Our commitment to innovation and quality makes us a trusted global partner.

Upgrade your production with YUANYANG’s homogenizer emulsifier mixers—engineered for excellence. (https://www.yuanymachinery.com/)

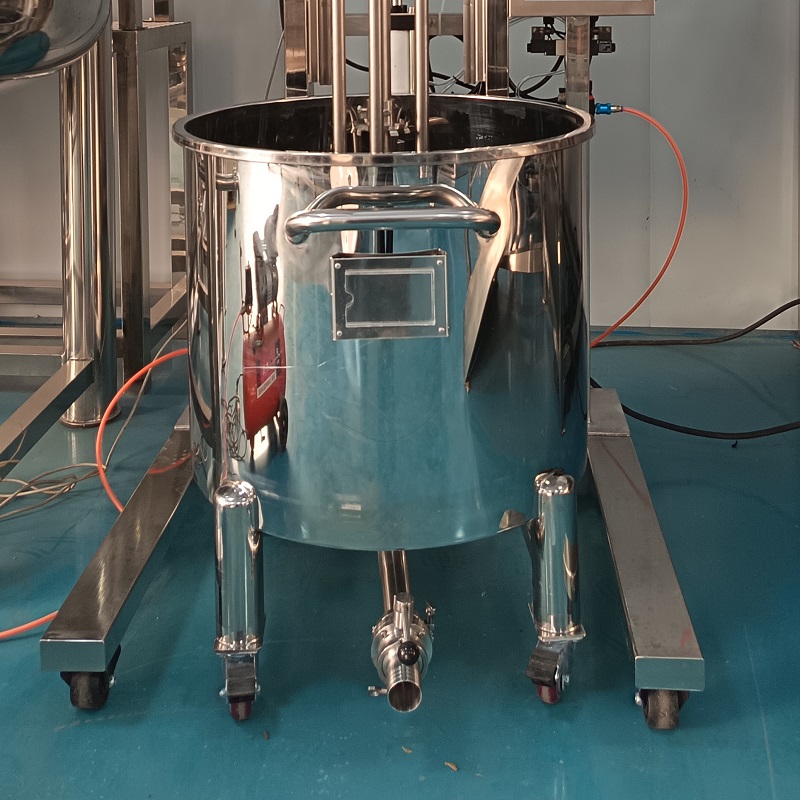

homogenizer emulsifier mixer Display

Can packing machinery be used for different film size?

The sachet packing machine for powders is suitable for different film width, but need to customize the bag-former for specific film width, then clients just need to replace the corresponding model for another film width.

What’s the rotation speed of the bottom homogenizer head of the liquid detergent mixer?

The standard homogenizer is with high speed 3000 rpm, we can customize other bigger speed according to actual needs.

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

Is this lid capping machine suitable for different shapes and sizes of bottles/jars?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery