YUANYANG Industrial Mixer & Homogenizer Solutions: Precision, Efficiency, Quality

YUANYANG Industrial Mixer & Homogenizer Solutions: Precision, Efficiency, Quality

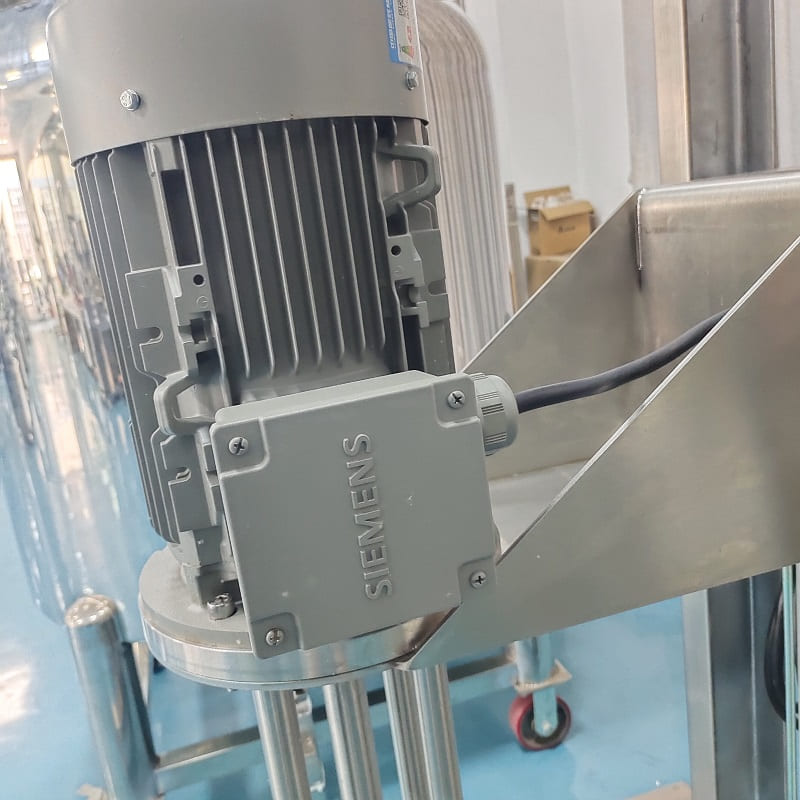

At YUANYANG, we understand that the heart of many production processes lies in precise and consistent mixing. As one of China's leading manufacturers of industrial mixers and agitators since 2008, we specialize in delivering cutting-edge industrial mixer homogenizer solutions engineered for superior performance. Our expertise ensures that your products achieve the perfect texture, stability, and homogeneity, crucial for industries ranging from pharmaceuticals and cosmetics to food and chemicals. Explore how YUANYANG can elevate your production standards with our advanced mixing technology.

Why Choose YUANYANG for Your Industrial Mixer & Homogenizer Needs?

YUANYANG stands out through its unwavering commitment to quality, innovation, and comprehensive customer support. Our deep understanding of mixing dynamics allows us to design and manufacture industrial mixers and homogenizers that meet the most stringent industry requirements. We are dedicated to providing not just equipment, but solutions that drive efficiency and enhance product quality. From intricate emulsifications to robust blending tasks, our machines are built for reliability and consistent output.

Engineered for Excellence: Our Advanced Mixer & Homogenizer Portfolio

Our extensive product range is specifically designed to address diverse industrial mixing challenges. Key offerings include:

- Vacuum Homogenizers: Ideal for sensitive products, preventing air incorporation and ensuring a smooth, stable, and bubble-free final product.

- Vacuum Emulsifying Mixers: Perfect for creating stable emulsions and suspensions with consistent particle sizes, crucial in cosmetic and pharmaceutical production.

- High Shear Mixers: Designed for intensive mixing, dispersion, and emulsification, drastically reducing processing times and achieving fine particle distribution.

Each industrial mixer and homogenizer in our portfolio is crafted with precision, incorporating robust materials and advanced control systems to guarantee optimal performance, longevity, and ease of operation.

Beyond Mixers: Complete Production Line & Turnkey Support

YUANYANG's commitment extends far beyond individual mixing units. Since 2008, we have focused on providing complete production line equipment. This includes a full suite of machinery such as storage tanks, filling machines, capping machines, labeling machines, sealing machines, inkjet printers, and water treatment equipment. What truly sets us apart is our holistic turnkey service approach. We offer free technical training and one-stop installation support, ensuring seamless integration and operation of your entire production setup from day one. Our products proudly carry multiple CE certifications, underscoring our dedication to safety and health standards for the European market and beyond.

Partner with YUANYANG for Unmatched Quality and Service

Our vision at YUANYANG is to become the best industrial mixer and agitator manufacturer in the world. We achieve this by consistently delivering superior products and unparalleled service. When you choose YUANYANG, you're partnering with an expert who understands your production challenges and provides solutions that deliver measurable results. Visit us at https://www.yuanymachinery.com/ to discover our range of industrial mixer homogenizer solutions and how we can support your journey towards manufacturing excellence.

industrial mixer homogenizer Display

Does your equipment support automated production?

Yes. Our equipment is highly automated, capable of full automation from ingredient preparation, mixing, emulsifying to filling and sealing, greatly reducing manual intervention and increasing production efficiency.

How does the rotor and stator work?

When the equipment is running, the rotor drives the blade to rotate at a high speed, generating a strong centrifugal force field, and forming a negative pressure zone in the center of the rotor, which inhales the material liquid. Under the action of centrifugal force, the material spreads from the center to the four sides, and is subjected to the stirring and shearing action of the blades during the diffusion process. The material is subjected to further shearing action in the narrow gap between the end face of the blade and the inner side of the stator tooth ring, and then enters the narrow gap between the rotating tooth and the fixed tooth of the inner ring, and is affected by mechanical force and hydrodynamics effect, resulting in shearing, friction and impact, so that dispersed phase particles or droplets are broken. As the linear speed of the tooth is gradually increased from the inner ring to the outer ring, the crushing environment of the material is continuously improved, and the purpose of homogenizing emulsification is finally achieved.

What’s the working principle of high shear homogenizer?

The shear mixer mainly through the high-speed relative rotation of the rotor and the stator to produce a strong shear force to achieve the refinement and homogenization of the material.

Can you make the leg longer, I need a higher discharge outlet?

Yes, the tank legs length is customized as well as the discharge outlet height.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery