YUANYANG Vacuum Mixer Homogenizers: Precision & Purity for Industrial Blending

YUANYANG Vacuum Mixer Homogenizers: Precision, Performance, Purity

In industries where product quality, consistency, and integrity are paramount – such as pharmaceuticals, cosmetics, food, and fine chemicals – the challenge of achieving perfectly blended, air-free, and stable emulsions is constant. YUANYANG, a leading manufacturer of industrial mixers and agitators in China since 2008, offers the solution: our advanced vacuum mixer homogenizers. Designed to address these critical needs, YUANYANG's equipment guarantees superior mixing performance, ensuring your products meet the highest standards of purity and stability.

Unparalleled Precision for Critical Processes

Our vacuum mixer homogenizer series is engineered for processes demanding meticulous control over mixing environments. By operating under vacuum, these machines effectively eliminate air incorporation, preventing oxidation, degradation, and the formation of unwanted air bubbles that can compromise product appearance and shelf life. The powerful homogenizing capabilities ensure a consistently fine particle size and uniform dispersion of ingredients, leading to incredibly stable emulsions and suspensions. This precision is vital for creating smooth, luxurious creams, stable pharmaceutical ointments, uniform food sauces, and high-quality chemical formulations.

Versatility Across Diverse Industries

YUANYANG's vacuum mixer homogenizers are not just machines; they are versatile workhorses indispensable across a multitude of sectors:

- Pharmaceuticals: Producing sterile, uniform creams, gels, and active ingredient suspensions.

- Cosmetics: Crafting luxurious lotions, foundations, and serums with perfect texture and stability.

- Food & Beverage: Manufacturing consistent sauces, dressings, mayonnaise, and dairy alternatives.

- Fine Chemicals: Developing high-performance adhesives, coatings, and specialized formulations.Our equipment is built to meet the stringent regulatory demands of each industry, ensuring compliance and operational excellence.

YUANYANG: Your Trusted Partner for Complete Solutions

Choosing YUANYANG means partnering with an industry leader committed to your success. Beyond our state-of-the-art vacuum homogenizers and high shear mixers, we offer comprehensive production line equipment, including storage tanks, filling, capping, labeling, and water treatment solutions. Since 2008, we've focused on providing complete, integrated systems. Our commitment extends to providing free technical training and one-stop installation support, offering a full set of turnkey services that streamline your operations from start to finish. With multiple CE certifications, YUANYANG proudly upholds the highest safety and health standards. Our vision is clear: to become the best industrial mixer and agitator manufacturer in the world, empowering our clients with unparalleled equipment and support.

Experience the YUANYANG difference – where innovation meets reliability. Visit (https://www.yuanymachinery.com/) to discover how our vacuum mixer homogenizer solutions can transform your production line.

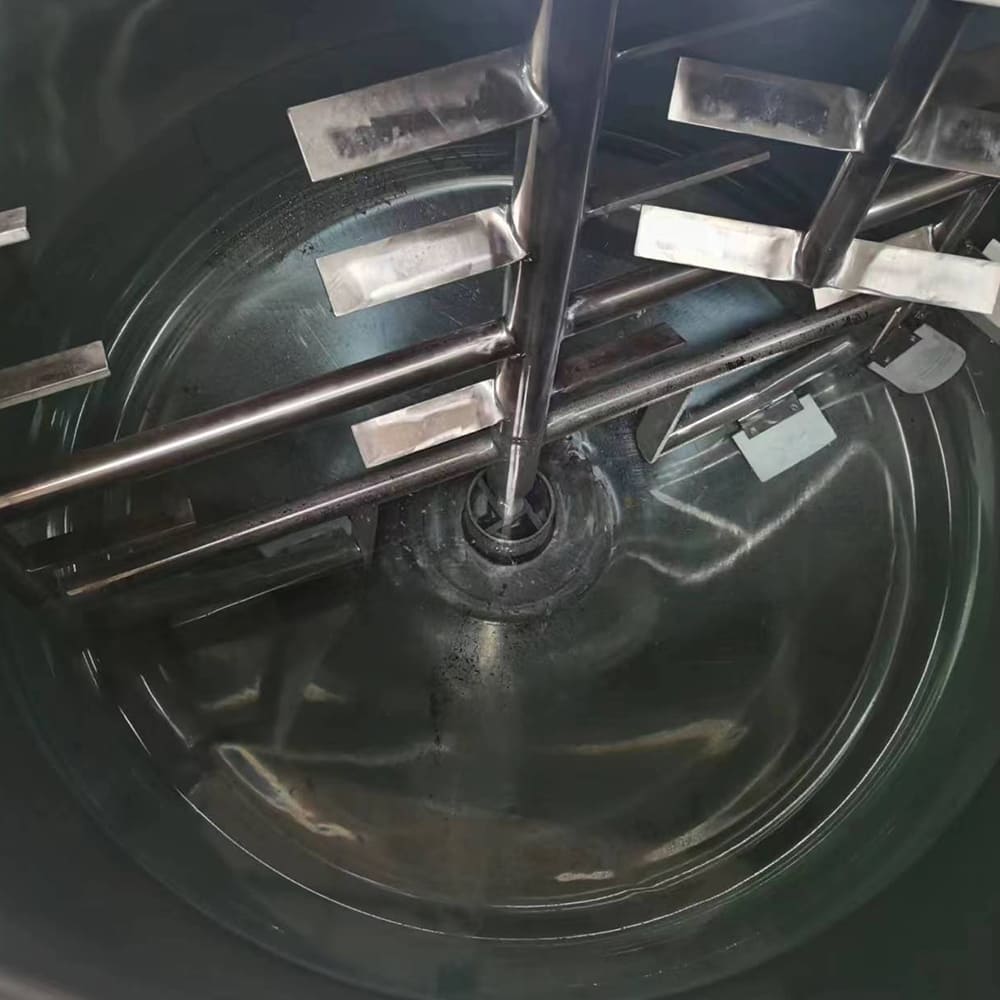

vacuum mixer homogenizer Display

What’s the material of the mixer with agitator ?

Yes, all the tank mixers are made of stainless steel, and the standard contact part is made of ss316L, other parts ss304, which meet GMP standards and is CE proved.

Why water pot and oil pot are needed?

The combination of water pot and oil pot plays a crucial role for cosmetic production equipment, which ensure the stability of the emulsification process and product quality through pretreatment and precise control each phase materials.

⦁ Pretreatment

The water pot and oil are equipped with heating and dispersing function. Each phase can be dissolved,dispersed,heated before entering into the main emulsifying equipment. The pretreatment improves emulsification efficiency, reduces unnecessary mixing problems, and ensures that the material is in the best condition during emulsification

⦁ Precise control

Each phase is with a separated pot. Through the precise control system of water pot and oil pot, the materials can be added to the emulsion pot according to the preset ratio and speed, to ensure the uniformity and stability of the mixing process. This precise control helps to produce a high quality, consistent product.

What’s the maximum height of the characters for the lot coding machine?

The maximum height of character can this continuous date printer machine print is 18mm.

Can the filling machine be connected with other machines, such as capping machine, bottle sorting machine?

Yes, this pneumatic filling machine is one of the complete filling line machines, user can tell the conveyor height of his current machine, we shall customize accordingly. If client buy a complete line from us, we will make every machine in a line or according to space.

Can you add circulation system for the shampoo production machine?

Yes, the mixing machines can be added with a pump with circulation system. We customize upon requirements.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery